China continues to be one of the world’s strongest manufacturing hubs. In 2026, many German businesses still rely on China for cost-effective production, specialized manufacturing, and scalable supply chains.

At the same time, Germany is one of the most regulated and quality-focused markets in the world. One wrong decision in sourcing can lead to shipment delays, rejected goods, compliance penalties, or damage to brand reputation.

This guide explains how German businesses can safely source products from China in 2026, while meeting EU regulations, protecting quality, and reducing operational risk.

Quick Answer for German Businesses

If you are a Germany-based business, safe sourcing from China in 2026 comes down to five non-negotiables:

- Verify the Chinese manufacturer properly

- Confirm EU and Germany compliance requirements

- Lock product specifications in writing

- Inspect products before shipment

- Control shipping and customs documentation for Germany

When these steps are followed, China sourcing becomes predictable and safe.

Why German Companies Still Source Products From China

Despite global supply chain changes, China remains attractive for German businesses due to:

- Advanced manufacturing infrastructure

- Competitive pricing for medium and large volumes

- Strong capabilities in electronics, machinery, batteries, and industrial components

- Faster production and tooling compared to many EU alternatives

However, cost savings only work when combined with structure and control. German businesses succeed when sourcing is planned, verified, and compliant from day one.

Step 1: Choose the Right Products for China Sourcing

Not every product is suitable for China sourcing.

China sourcing works best for:

- Electronics and electrical components

- Machinery and industrial equipment

- Batteries and energy storage systems

- Consumer goods with stable specifications

- Private label products with defined quality standards

Before contacting suppliers, German businesses should prepare:

- Clear product specifications

- Material and component requirements

- Quality tolerance levels

- Packaging and labeling standards

- EU compliance requirements

Clear documentation prevents misunderstandings and protects quality later in the process.

Step 2: Verify Chinese Manufacturers Properly

Supplier verification is one of the biggest risk areas in China sourcing.

A reliable Chinese manufacturer should:

- Be a direct factory or clearly identified trading company

- Hold a valid Chinese business license

- Have export experience with EU or German buyers

- Provide compliance and testing documentation

Verification steps German businesses should follow:

- Request business registration and export license

- Confirm factory location and operating history

- Ask for references from EU customers

- Use third-party factory audits when possible

Never rely only on online listings or email conversations. Real verification reduces supplier risk significantly.

Step 3: Understand EU and Germany Compliance Requirements

Germany follows strict EU regulations. If you sell products in Germany, you are legally responsible for compliance, even if manufacturing happens in China.

Common requirements include:

- CE marking for applicable product categories

- EU Declaration of Conformity

- RoHS compliance for electronics

- REACH compliance for chemicals and materials

- EU Battery Regulation for lithium and energy products

Important for Germany:

Certificates must be valid for the EU market and issued by recognized testing laboratories. Reused or fake certificates are a common issue in China sourcing and must be verified carefully.

Always confirm which regulations apply to your exact product category.

Step 4: Implement Quality Control at Every Stage

Quality control should not be limited to final inspection.

A safe sourcing process includes:

- Pre-production sample approval

- In-process inspections during manufacturing

- Pre-shipment inspection before final payment

- Random testing for regulated products

Skipping inspections often results in:

- Inconsistent quality

- Specification mismatches

- Defective products

- Expensive returns or rework

Third-party inspections in China help ensure products meet agreed standards before shipment.

Step 5: Use Clear Contracts and Payment Terms

Clear contracts protect both the buyer and the supplier.

A strong sourcing contract should define:

- Product specifications and quality standards

- Inspection and approval rights

- Delivery timelines

- Penalties for non-compliance

- Intellectual property protection

Recommended payment practices:

- Avoid full upfront payments

- Use milestone-based payments

- Release final payment only after inspection approval

- Use secure international payment methods

Clear agreements reduce disputes and protect German businesses legally.

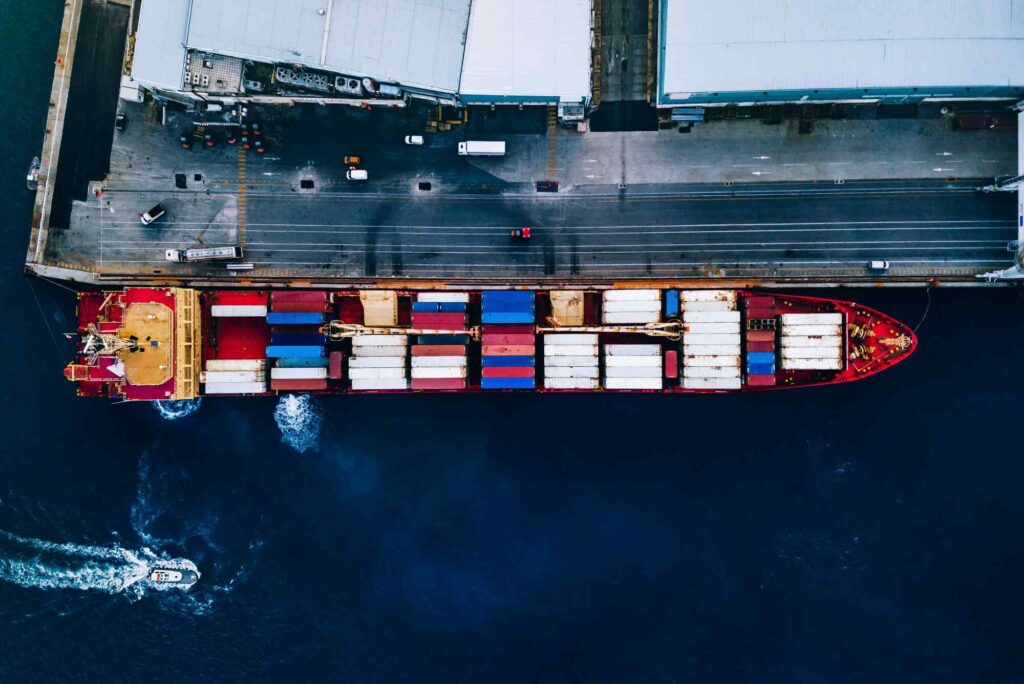

Step 6: Plan Logistics and Customs for Germany

Logistics mistakes can eliminate all sourcing savings.

German businesses should ensure:

- Incoterms are clearly defined

- Packaging and labeling meet EU requirements

- HS codes are accurate

- Commercial invoices and packing lists are complete

German customs authorities are strict. Incorrect documentation can lead to inspections, delays, or penalties.

Working with freight forwarders experienced in China-to-Germany shipping is strongly recommended.

Step 7: Protect Your Brand and Intellectual Property

Intellectual property protection still matters in 2026.

German businesses should:

- Register trademarks in China when necessary

- Share only essential design information

- Use non-disclosure agreements

- Work with trusted and verified manufacturers

Brand protection is much easier when handled early rather than after problems occur.

Common China Sourcing Mistakes German Businesses Must Avoid

Many sourcing failures come from avoidable mistakes:

- Choosing suppliers based only on price

- Skipping factory verification

- Ignoring EU compliance requirements

- Trusting supplier-provided certificates without verification

- Skipping inspections to reduce costs

Safe sourcing is not about speed. It is about control and consistency.

Why German Businesses Are Moving to Structured Sourcing Models

In 2026, successful German companies follow structured sourcing systems instead of one-off buying.

These systems include:

- Verified supplier networks

- Documented compliance processes

- Regular inspections

- Clear logistics planning

Structured sourcing reduces risk and supports long-term growth in the German and EU markets.

Frequently Asked Questions

Is it legal for German companies to source products from China?

Yes. It is legal, but products must comply with applicable EU regulations and be correctly documented for import into Germany.

Do all products need CE marking in Germany?

No. Only specific product categories require CE marking. Requirements depend on the product type.

How can German businesses verify Chinese manufacturers?

By checking business licenses, export capability, EU client experience, and using third-party audits when needed.

What is the safest way to manage quality when sourcing from China?

Use written specifications, approve samples, inspect during production, and conduct pre-shipment inspections.

What causes delays at German customs most often?

Incorrect HS codes, missing documents, labeling errors, and unclear Incoterms.

Final Thoughts: Safe China Sourcing Is Achievable for German Businesses

China sourcing in 2026 is not risky when done correctly. It becomes risky only when shortcuts are taken.

German businesses that invest in verification, compliance, inspections, and structured processes can safely source from China while maintaining high quality and regulatory standards.

The goal is not just lower costs. The goal is reliability, compliance, and long-term brand trust in Germany and across the EU.