Automated Manufacturing Equipment Procurement

Trusted Sourcing. Transparent Pricing. On-Time Delivery. No Surprises.

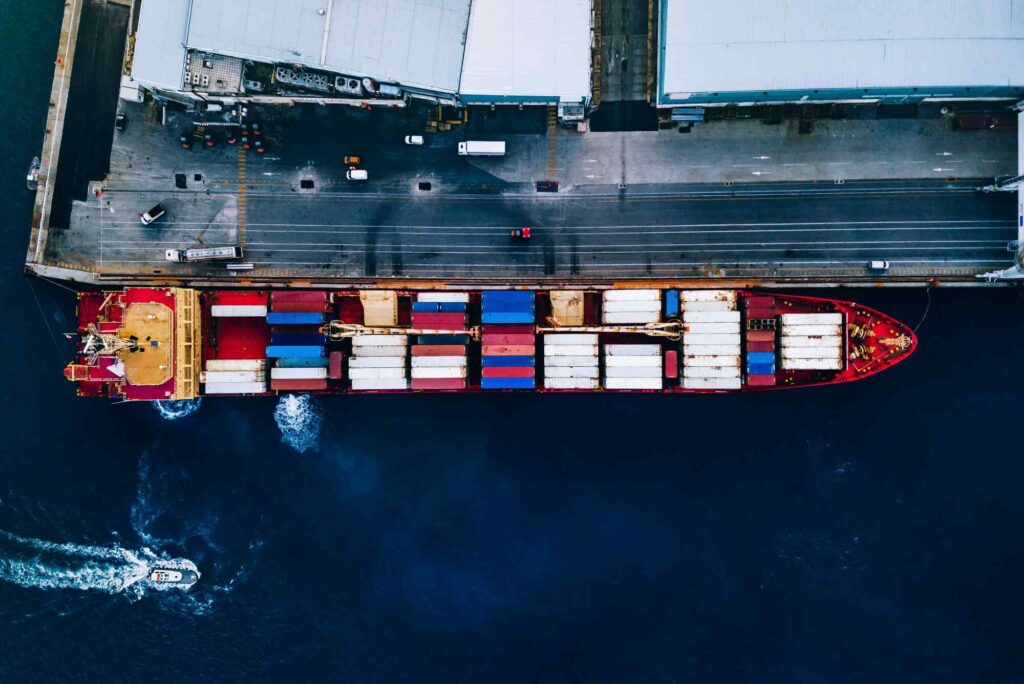

Factory automation and assembly equipment sourced directly from verified manufacturers in China, with disciplined documentation, technical validation, and structured Delivery Duty Paid (DDP) import into Germany.

What you get:

- Verified automation equipment manufacturers in China

- CE-compliant documentation and safety validation

- Sample or reference evaluation before commitment

- DDP delivery across Germany with full import handling

Get In Touch With Us

China Product Sourcing for German Businesses Made Simple

Get reliable suppliers, verified factories, and end to end procurement support directly from China.

Perfect for German companies that want quality, speed, and low cost sourcing without the stress.

What you get:

- Verified manufacturers and factory audits

- Full procurement management with quality checks

- Hassle free logistics with DDP delivery to Germany

- Transparent pricing with no surprises

Get In Touch With Us

Managing EV Infrastructure Procurement Risk in Germany

As EV adoption accelerates across Germany, companies face increasing pressure to deploy charging infrastructure that is compliant, scalable, and installation-ready. Procurement errors such as incomplete documentation, incompatible components, or delayed shipments can disrupt approvals and project timelines.

EV charging projects involve multiple technical and regulatory considerations, including grid compatibility, safety standards, and long-term operational reliability. Procurement teams are expected to manage these requirements while working against fixed schedules and limited tolerance for rework.

Our role is to reduce procurement risk at the sourcing stage by ensuring supplier reliability, technical alignment, and delivery predictability before orders are confirmed.

What We Help You Source

We support sourcing across key automation categories used in German manufacturing environments.

Factory Automation Systems

Integrated automation solutions designed to improve production efficiency, consistency, and throughput in manufacturing plants.

Assembly Line Equipment

Automated and semi-automated assembly line equipment for structured, repeatable production workflows.

Packaging Automation Machines

End-of-line and mid-line packaging automation for speed, precision, and reduced manual handling.

Industrial Automation Equipment

Machinery and systems supporting motion control, material handling, process automation, and industrial operations.

Custom Automation Solutions

Configuration-based automation equipment aligned with specific production layouts, output targets, and process requirements.

Production Testing & Inspection Systems

Automated testing and inspection equipment used to verify product accuracy, consistency, and compliance during production.

If your company in Germany needs trusted battery sourcing from China, we handle every step from supplier selection to delivery.

Why Structured Sourcing Works in Germany

Built to Protect Production Timelines and System Integration

As production scales, German manufacturers face increasing pressure around equipment reliability, integration accuracy, and delivery timelines.

A single mismatch in specifications or incomplete documentation can delay commissioning and disrupt operations.

As production scales, German manufacturers face increasing pressure around equipment reliability, integration accuracy, and delivery timelines. A single mismatch in specifications or incomplete documentation can delay commissioning and disrupt operations.

Our Automation Equipment Sourcing Model

Bavaria Traders operates as a sourcing and procurement partner. We do not manufacture or resell automation equipment. Instead, we help German companies access qualified automation equipment manufacturers in China while maintaining control throughout the process.

Each manufacturer is evaluated against defined production, certification, and delivery benchmarks before being shortlisted. This ensures sourcing decisions are based on capability, not assumptions.

Quality Review, Samples & Technical Validation

Automation equipment sourcing requires more than price comparison. German buyers rely on traceable specifications and predictable performance.

Our sourcing workflow includes manufacturer capability assessment, technical documentation review, optional sample or reference validation, production confirmation, and inspection coordination.

This structured oversight reduces sourcing risk before equipment reaches your facility.

Delivery Duty Paid (DDP) Shipping for Automation Equipment

Automation machinery requires compliant packaging, accurate labeling, and complete import documentation. We manage the full Delivery Duty Paid (DDP) process so equipment arrives in Germany fully cleared and ready for installation.

From export coordination in China to customs clearance and final delivery, logistics are handled end to end to keep timelines predictable.

Who We Support Across Germany

We work with organizations involved in the planning, rollout, and operation of EV charging infrastructure across Germany. This includes companies managing commercial properties, vehicle fleets, and charging networks, as well as EPC contractors and engineering teams responsible for system deployment.

Our sourcing support is also used by industrial and logistics facilities integrating EV charging into their operations, municipal and infrastructure-led projects, and wholesalers or distributors supplying EV equipment to the German market.

The common factor is the need for reliable equipment, correct documentation, and predictable delivery to support real-world installation timelines.

How Our Process Works

Free Discovery Call

We understand your product needs, volumes, timelines, specifications, and target prices.

Supplier Research

We shortlist verified factories and request formal quotations with detailed specs.

Quotation Report

You get a clean comparison sheet with prices, MOQs, quality levels, and lead times.

Samples & Testing

We arrange samples, test them, and send video reports before bulk order confirmation.

Order Finalization

We manage negotiations, contracts, payment terms, and track timelines end to end now!

Production Control

Weekly factory updates, quality checks and real time reporting throughout process EU.

Delivery to Germany

We manage logistics and ensure smooth delivery directly to your address in Germany EU!

The Process We Follow

Step 1:

Free Discovery Call

We understand your product needs, volumes, timelines, specifications, and target prices.

Step 2:

Supplier Research & RFQ

We shortlist verified factories and request formal quotations with detailed specs.

Step 3:

Quotation Report

You get a clean comparison sheet with prices, MOQs, quality levels, and lead times.

Step 4:

Samples & Testing

We arrange samples, test them, and send video reports before bulk order confirmation.

Step 5:

Order Finalization

We handle negotiation, contracts, payment terms, and timeline tracking.

Step 6:

Production Monitoring

Weekly factory updates, QC checks, and real time reporting.

Step 7:

Delivery to Germany (DDP)

We manage logistics and ensure smooth delivery to your address in Germany.

Bavaria Traders Sourcing Advantages

Direct Manufacturer Access

We work only with verified factories and production partners in China. This gives you consistent pricing, reliable product quality, and a controlled sourcing process backed by real supplier checks.

Technical & Certification Support

Every order is backed by document review including CE, RoHS, UN38.3, and MSDS validation. You receive clear product data before purchase to support safe installation and EU market requirements.

Sampling & Approvals

We share quotation comparison reports, supplier evaluations, and structured sourcing data. You gain pricing clarity and confidence, supported by optional sample testing before committing to bulk orders

Full Visibility & Delivery To Germany

Across production we share photo/video progress updates, timeline tracking, and DDP logistics support to Germany. Products arrive duty paid, documented, and ready for your operations.

From Bavaria to China: Our Story!

From the early stages, we worked closely with German companies, especially in manufacturing-driven industries. This gave us first-hand exposure to the level of precision, structure, and reliability expected in one of the world’s most quality-focused industrial markets.

Many of these experiences came from working with businesses influenced by Bavaria’s strong engineering standards. Over time, this shaped how we approach China product sourcing for Germany.

The name Bavaria Traders reflects this foundation. We follow disciplined, process-driven standards in every aspect of our work, from supplier evaluation and quality control to clear and transparent communication.

Our focus is on building dependable, long-term partnerships for product sourcing from China to Germany, China manufacturing for German companies, and connecting reliable China suppliers for Germany while maintaining the highest standards throughout the process.

FAQs

No. Manufacturers produce the equipment. Bavaria Traders manages sourcing, verification, and import coordination.

Yes. Configuration-based and application-specific equipment can be reviewed.

Yes. Packaging automation is a common sourcing category we support.

Yes. Delivery Duty Paid (DDP) shipping is provided.

We take projects that align with our sourcing and verification capabilities.

Your Trusted Global Sourcing Partner from China to Businesses Worldwide

Product Categories

Contact

Call/WhatsApp: +86 185 2939 1629

Office #B34, 5th Floor, No. 604 Renmin North Road, Yuexiu District, Guangzhou

Scan below to contact us on WeChat